Description :

Because of the high mechanical strength of annealed parts, they can be made with smaller cross sections to save weight, and they can be made with thinner stock to save money.In addition to having twice the yield strength of AISI 304, NITRONIC 60 is a stainless steel alloyed with silicon and manganese. It is resistant to wear, galling, and fretting because of the increased silicon and manganese content. It is suitable for use at temperatures up to 1000 degrees Celsius. A steel's corrosion resistance is typically measured in millimetres per inch of thickness (mm/in). Chloride pitting resistance, stress corrosion cracking resistance, and crevice corrosion resistance are all higher than those of AISI 316L when tested in the lab under these conditions.

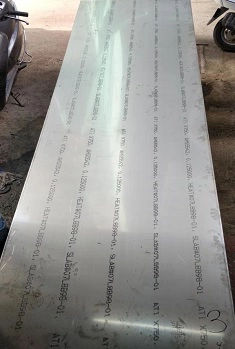

Nitronic 60 (Alloy 218, UNS S21800) is a high-performance grade of stainless steel that offers superior corrosion resistance and excellent mechanical properties at an affordable price. This alloy is perfect for applications such as pump shafts, valves, fasteners, and other parts exposed to highly corrosive marine environments. Due to their excellent mechanical properties, Nitronic 60 Rods are used for a wide range of applications across many industries including aerospace, oil and gas production, petrochemical processing, and water treatment systems. Alloy-218 Round Bar is particularly popular in the medical industry due to its non-magnetic properties which make it ideal for use in MRI scanners and other medical imaging equipment. Different types of products are available, such as Nitronic 50 Round Bars, Nitronic 50 Forgings, etc.

Nitronic 60 Specifications :-

-

Nitronic 60

-

ASTM A 479 , A 276 , A 182 STD

-

Solution Annealed

Nitronic 60 Application :-

Applications using NITRONIC 60 are valve stems, seats and trim, fastening systems, screening, pins, bushings and roller bearings, pump shafts and rings.Other uses include wear plates, rails guides, and bridge pins. This alloy provides a significant lower cost way to fight wear and galling compared to Nickel or Cobalt based alloys.

.webp)