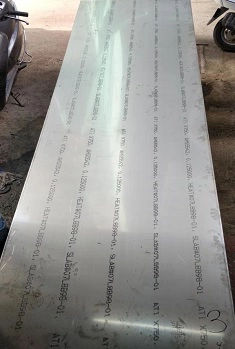

Description :

Alloy 825 is a nickel-iron-chromium alloy that exhibits excellent resistance to general corrosion, pitting and crevice corrosion, intergranular corrosion, and stress corrosion cracking. Molybdenum and copper additions provide resistance to reducing agents and acids.Chloride-ion stress-corrosion cracking is adequate to prevent chloride-ion stress. Molybdenum contributes to the resistance of metals to pitting and crevice corrosion. Chromium provides resistance to oxidising conditions, while titanium prevents the alloy from becoming sensitised to intergranular corrosion.

Alloy 825 exhibits excellent mechanical properties at temperatures ranging from cryogenic to moderately high temperatures near 540°C. Additionally, it has high impact strength at room temperature and retains its strength when frozen. Cold working can significantly strengthen this alloy

Inconel 825 Specification :-

-

ASTM B425

-

Virtually immune to chlorine ion stress corrosion cracking

-

UNS N08825

-

BS 3076 NA 16 - 1989

-

Werkstoff Nr. 2.4858

Inconel 825 Characteristics :-

-

Excellent resistance to reducing and oxidizing acids

-

Good resistance to stress-corrosion cracking

-

Reasonable resistance to localized attacks such as pitting and crevice corrosion

-

Very resistant to sulfuric and phosphoric acids

-

Excellent mechanical properties at both room

-

Elevated temperatures up to approx. 1000°F

-

Suitable for pressure-vessel use at wall temperatures up to 800°F

Inconel 825 Application :-

-

Chemical processing

-

Pollution-control

-

Oil and gas well piping

-

Nuclear fuel reprocessing

-

Components in Pickling equipment like heating coils, tanks, baskets and chains

-

Acid production

.webp)