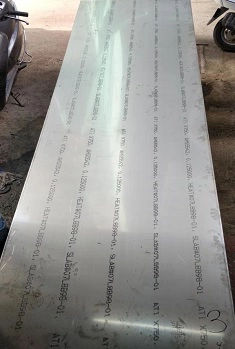

Description :

For technical applications requiring resistance to heat and corrosion, Inconel 601 Ni-Cr-Fe alloy is a versatile material. The ability of Inconel alloy 601 to withstand high temperatures against oxidation is one of its best qualities. Along with having a high mechanical strength, the alloy is easily formed, machined, and welded. It also has good resistance to aqueous corrosion. There is a significant level of metallurgical stability in this face-centered cubic solid solution. Many corrosive media and high-temperature conditions are resistant to the nickel basis of ASME SB167 Inconel 601 Product, which is combined with a significant chromium component. The aluminum component increases oxidation resistance even more.

The resistance to oxidation at high temperatures—up to 1250C—under harsh circumstances, such as periodic heating and cooling, is one of UNS N06601 characteristics. This is made feasible by the strongly adhering oxide layer that resists spalling present in Inconel 601 Products. Excellent resistance to carburization and carbon nitriding conditions are also present. It has been shown to have good resistance to oxidizing sulfur-bearing atmospheres at elevated temperatures because of its high chromium and somewhat aluminum content.Among the most well-known applications are Dishes, containers, and fittings utilized in diverse thermal processes like carbon nitriding and carburizing. XH60BT GOST Highly suitable for high velocity gas burners, wire mesh belts, strand annealing, radiant tubes, and refractory anchors, among other applications. Cans in catalyst support grids and ammonia reformers that are used to produce nitric acid are insulated. gasoline engine exhaust systems with thermal reactors. created combustion chambers. The power generation business uses ash trays and tube supports.

Inconel 601 Characteristics :-

-

Outstanding oxidation resistance to 2200° F

-

Resists spalling even under severe thermal cycling conditions

-

Highly resistant to carburization

-

Good creep rupture strength

-

Metallurgical stability

Inconel 601 Application :-

-

Chemical Processing

-

Aerospace

-

Heat treating industry

-

Power generation

-

Heat treating muffles and retorts

-

Radiant tubes

-

Catalyst support grids in nitric acid production

-

Steam superheater tube supports

.webp)