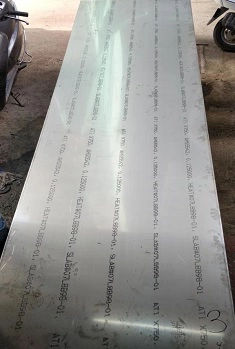

Description :

Tough Alloys is instrumental in supplying, trading and manufacturing an extensive collection of Hastelloy material to the respected customers. We are dedicated to offer them in the best rates. In order to make sure in blemish free design, we inspect these Hastelloy Products on PED quality constraints.

Hastelloy Surface Cold Rolled products are manufactured and designed at our high-tech manufacturing unit, which is fixed by means of strictly cutting – edge amenities and machines. Tough Alloys also offer these products in different grades in customized sizes and shapes to our customers. Hastelloy Circle is a Ni – Cr – Mo – W alloy, which offers resistance to pitting, stress-corrosion cracking, and crevice corrosion. Annealing of Hastelloy Shim products after working is advised and should be performed at a temperature between 2050 Degree F and 2150 Degree F followed by a rapid quench in a protective atmosphere or in an agitated reducing quench bath. Being the Hastelloy Alloy Slatting suppliers we are bound to properties like their resistance to chloride-induced stress corrosion cracking. The registered trademark name, Hastelloy Alloy Perforated Coils are applied as the prefix name to more than twenty different highly corrosion resistant metal alloys produced by us.

Hastelloy C22 Application :-

-

Digesters and bleach plants in the paper industry.

-

Components exposed to sour gas.

-

Heat treating industry

-

Equipment for flue-gas desulfurisation plants.

-

Evaporators, heat exchangers, filters and mixers used in sulfuric acid environments.

-

Sulfuric acid reactors.

-

Organic chloride process equipment

-

Equipment for processes utilizing halide or acid catalysts.

.webp)