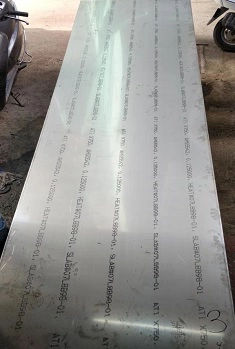

Description :

Hastelloy X is a nickel-based superalloy ideal for many applications such as gas turbine engine, jet engines, industrial furnace, chemical processing and high-temperature applications. Gas turbine engines use ASTM B435 Hastelloy X Cold Rolled products for flame holders, spray bars, transition ducts, combustor cans and other combustion-related parts.Alloy X also performs well in aircraft parts, including jet engine tailpipes, afterburner components, and cabin heaters. ASME SB435 Hastelloy X is known for its excellent high temperature strength withstanding up to 2200°F. The alloy can also be easily fabricated with forming and welding characteristics by both manual and automatic methods.

Additionally, Hastelloy DIN 2.4665 Hot Rolled products are corrosion resistant, heat resistant and oxidation resistant, being able to withstand reducing or neutral atmospheres and oxidation.Hastelloy UNS N06002 Products have a number of outstanding attributes to provide like having rugged construction, corrosion-resistance, precise dimensions, and so on. Please call us for a more in-depth look at additional uses for Hastelloy X Surface Cold products that includes some comparative corrosion resistance data, media, concentrations and temperatures. For more information on FASTWELL’s Pipe and Piping Systems, please see our Hastelloy X Tube page.

Hastelloy X features :-

-

High degree of oxidation resistance up to 2200° F

-

Outstanding high-temperature strength

-

Easily fabricated including forming and welding

-

Good ductility after prolonged exposure at high-temperatures

-

Good resistance to chloride stress-corrosion cracking

-

Resistant to carburization and nitriding

-

Develops a protective oxide film that does not spall off

Hastelloy X Application :-

-

Gas turbine engines

-

Transition ducts

-

Combustor cans

-

Spray bars and flame holders

-

Afterburners, tailpipes, and cabin heaters

-

Chemical processing retorts, muffles, and tubing

.webp)