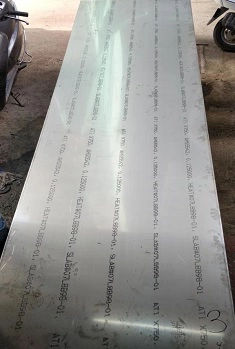

Description :

800HT demonstrates the superior cold forming characteristics associated with nickel-chromium alloys. When the grain size is extensively cold formed, a visible undulating surface known as "orange peel" results. 800HT is a stainless steel that can be welded using conventional techniques. The alloy is commonly used in ethylene pyrolysis, hydrocarbon cracking, and furnaces for the cracking of vinyl chloride, diphenol, and acetic acid. Additionally, the alloy is used in the manufacture of valves, fittings, and other components that are subjected to corrosive attack between 1100 and 1800 degrees Fahrenheit.Round bar with a diameter of 3/4" to 6", as well as thin gauge sheet and plate. Incoloy 800 H material is available in random lengths, cut to length, and machined to customer specifications. Drilling, threading, milling, CNC shapes, turning, tapping, and flange manufacturing are all examples of machining.

Alloy 800H/800HT (/ W.Nr. 1.4958 & 1.4959) are solid solution strengthened, iron- nickel-chromium alloys, typically offered as one, dual certified alloy meeting the elemental requirements of both alloys. The principle difference between alloy 800H and 800HT® material is the restricted aluminum and titanium content in 800HT®, which results in higher creep and stress rupture properties. Both Alloy 800H and 800HT® are superior to Alloy 800 (UNS N08800), having greater creep and stress rupture properties. The alloy is typically used for applications involving long-term exposure to high-temperatures where resistance is needed from oxidation, carburization and other types of high-temperature corrosion. Hydrocarbon processing, heat-treat furnaces and power generation are some of the most common applications where 800H & 800HT® is utilized. Pressure vessels and vessel components constructed from 800H and 800HT® are approved under the ASME, Boiler and Pressure Vessel Code, Section VIII, Division 1.

Inconel 800H/800HT Characteristics :-

-

High temperature strength

-

High creep rupture strength

-

Non-magnetic

-

Resistant to oxidation and carburization in high temperature environments

-

Good corrosion resistance in many acidic environments

-

Good resistance to many sulfur-containing atmospheres

Inconel 800H/800HT Application :-

-

Chemical industry

-

Aerospace

-

Heat treating industry

-

Pulp and paper industry

-

Nuclear Engineering

-

Gas turbine components