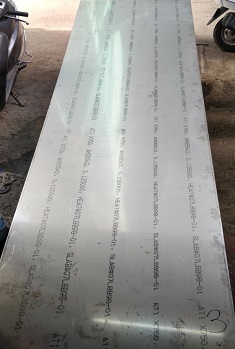

Description :

Utilized in temperatures ranging from -423° to 1300°F, Inconel 718 is a high-strength, corrosion-resistant nickel-chromium alloy. This age-hardenable alloy is easily produced, even into intricate pieces, and it has excellent welding properties, particularly in terms of its resistance to postweld cracking. INCONEL alloy 718 W.Nr. 2.4668 is used in many different applications due to its economical and simple fabrication process, as well as its strong tensile, fatigue, creep, and rupture strengths.pieces made of formed sheet metal for gas turbine engines installed on land and in airplanes, cryogenic tankage, rings, casings, and liquid-fueled rocket components. Fasteners and instrumentation parts are further applications for UNS N07718 inconel alloy 718

Inconel alloy 718 is manufactured by Tough Alloys and is utilized in oil field applications. The production of this material must adhere to NACE specification MR0175, which stipulates that the aged and solution-annealed material must have a maximum hardness value of 40 Rockwell C. This material undergoes a solution heat treatment between 1850 and 1900 °F, is aged for six to eight hours at 1450 °F, and is then air cooled.

Inconel 718 Specifiation :-

-

ASTM B637

-

UNS N07718

-

API 6ACRA

-

AMS 5662/5663

-

NACE MR0175/ISO15156

-

Werkstoff Nr. 2.4856

Inconel 718 Application :-

-

Chemical processing

-

Aerospace

-

Liquid fuel rocket motor components

-

Pollution-control equipment

-

Nuclear reactors

-

Cryogenic storage tanks

-

Valves, fasteners, springs, mandrels, tubing hangers

-

Well head completion equipment and blow out preventers (BOP’s)

-

Gas turbine engine parts