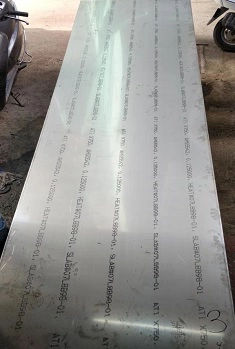

Description :

Tough Alloys is one of the largest exporter, manufacturer and supplier of Nimonic 80 products in India. NIMONIC 80 products is a nickel-chromium alloy similar to NIMONIC alloy 75 but made precipitation hardenable by additions of aluminium and titanium. NIMONIC 80 products have good corrosion and oxidation resistance and high tensile and creep-rupture properties at temperatures to 1500 Deg F (815 Deg C).These NIMONIC Alloy 80 products are used for gas-turbine components (blades, rings, and discs), bolts, tube supports in nuclear steam generators, die-casting inserts and cores, and exhaust valves in internal-combustion engines. Also known UNS N07080 Bars, our Nimonic Alloy 80 products are accessible to our valuable customers in different range of diameters, wall thicknesses and sizes in customized form and also at quite affordable rates.

Due to its ability to withstand very high temperatures, Nimonic is ideal for use in aircraft parts and gas turbine components. The common use of this alloy is found in exhaust nozzles on jet engines, for instance, where the pressure and heat are extreme. It is available in Tough Alloys in different grades. In addition to receiving ISO9001:2000 and AS9100 certification, Tough Alloys is well-known for offering one of the fastest turnaround times in the custom forging industry. If you are looking for Nimonic, then order in customized forged shapes such as discs, mandrel rings, and shafts. To learn more about the superior products and services offered by Tough Alloys, please call us or send an e-mail to ask your queries.

Features of Nimonic 80

-

Largely superseded by Nimonic 90 & Inconel X-750

-

Still specified for nuclear applications due to low cobalt content

-

Age hardenable

-

High temperature dynamic applications^^

Designations

-

W.Nr 2.4952

-

W.Nr 2.4631

-

UNS N07080

-

AWS 031

Specifications

-

ASTM B637

-

BS 3076 NA 20

-

BS HR 1

-

BS HR 601

.webp)