Description :

Our Nimonic 263 is supplied in the annealed condition, offering excellent ductility that makes it suitable for both cold forming and hot working processes. When it comes to welding Nimonic 263, we recommend using filler wire with a matching composition in both TIG and MIG forms to ensure optimal results.

The werkstoff nr. 2.4650 Nimonic 263 was originally a nickel alloy material, which was originally designed to have a high flow limit in sheet materials. Today, it is possible to find this material in many different forms. There is no requirement to heat the pre-weld material in this weldable material. Nimonic Alloy 263 material is basically a nickel alloy made of nickel-chromium-cobalt combination and the molybdenum element contained in the material adds extra corrosion resistance to the material. You can contact FASTWELL for detailed information on this material that has been aged by aging and hardened, and this material that can be hardened by aging can have excellent corrosion resistance, especially at high temperatures.

Alloy 263 material is often more suitable for use as Tube. As with other nimonic materials, gas turbine blades, turbine discs, cast parts and sheet metal materials are used in many different places in this material. In addition, the use of material 263 as welding material ensures that the welded areas have a more flexible and durable structure.

NImonic 263 Specifications :-

-

UNS N07263

-

Werkstoff Nr. 2.4650

-

BS HR10 Rod and Bar

-

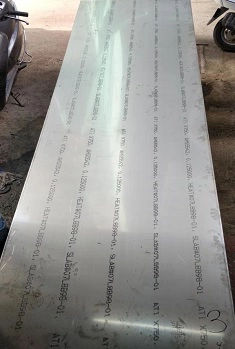

BS HR 206 Plate, Sheet, Strip

-

BS HR 404 Seamless Tube

-

AECMA PrEn 2199 Bar

-

AECMA PrEn 2200 Forgings

-

AECMA PrEn 2201 Bar

-

AECMA PrEn 2202 Tube

-

AECMA PrEn 2203 Sheet, Strip

-

AECMA PrEn 2418 Plate

-

DIN 17750 Plate, Sheet, Strip

-

DIN 17751 Pipe and Tube

-

DIN 17752 Bar and Rod

-

DIN 17753 Wire

-

DIN 17754 Forgings

.webp)